HEROLASER

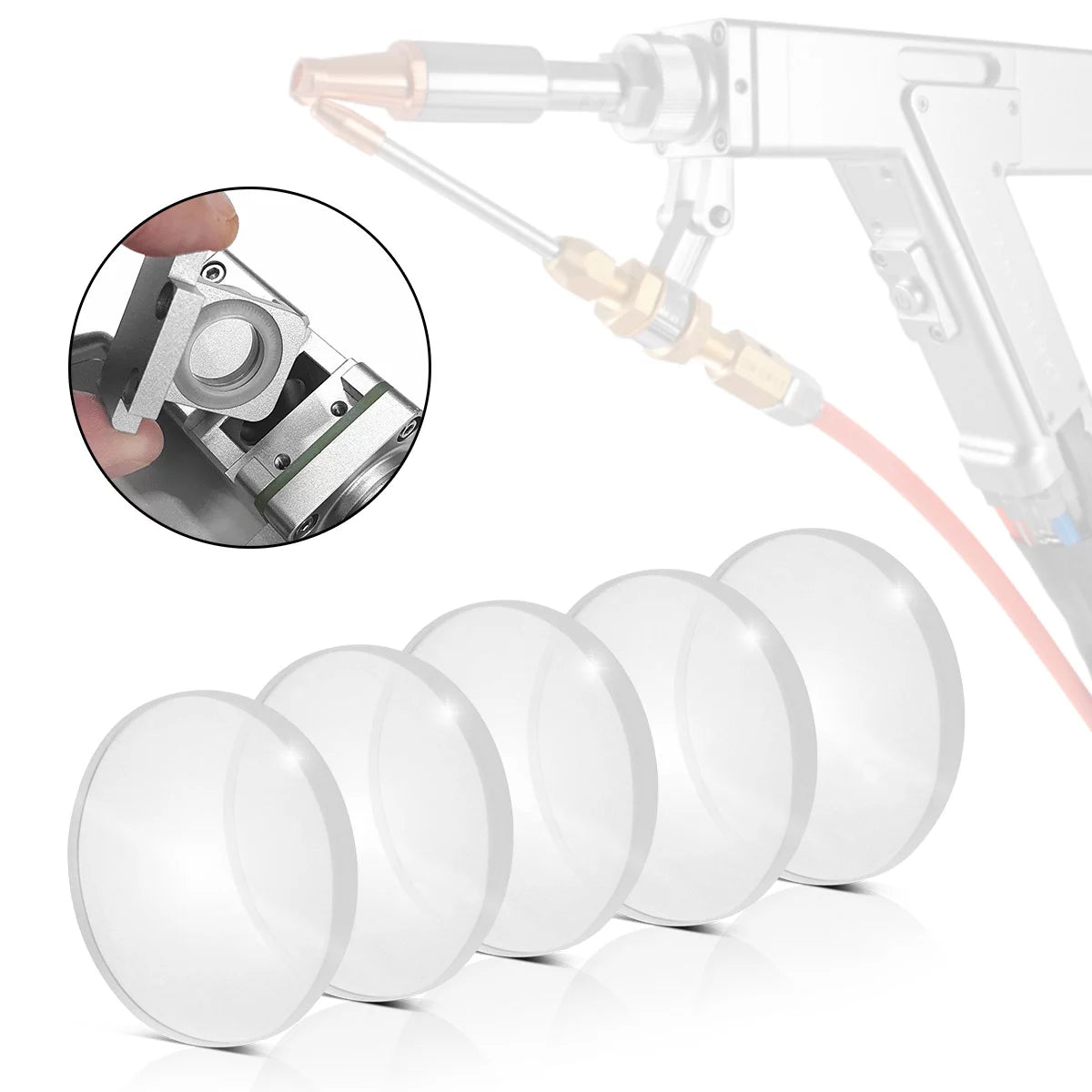

Laser Lens

Choose options

Herolaser 激光防护镜片组做工精良,适用于700瓦的手持式激光焊枪/激光焊机。玻璃镜片组与激光焊枪完美匹配,也适用于技术匹配的国外品牌光纤激光器。手持式激光焊机的专业配件非常适合工业、手工艺和 DIY 领域的焊接、切割 (CUT) 和清洁 (CLEAN) 专业应用。

Dampen a dust-free cloth with alcohol and gently wipe around the protective lens. The purpose of this step is to prevent dust from entering the cavity during disassembly.

Cleaning Hands:

Clean hands with soap or detergent and wear lightweight, clean white gloves. Avoid any part of the hands touching the lens. When removing the lens, handle it from the side.

Disassembly:

1. In a relatively dust-free environment, loosen the screws of the protective lens drawer and remove the protective lens drawer assembly.

2. Take out the lens retaining ring (with the white sliding ring facing up).

3. Remove the protective lens and replace it with a new one. The protective lens is a flat lens that can be detached by pressing it to separate it from the sealing ring. When installing the lens, place it first and then press the sealing ring tightly. If there is dust on the surface of the protective lens, use a dust-free cloth or lint-free cotton swab with a small amount of non-water-based alcohol to wipe the lens in one direction.

4. Once the lens is placed in the protective lens holder, press the lens retaining ring (with the white sliding ring facing up) onto the lens. At this point, the protective lens should be pressed into the groove of the lens retaining ring.

5. Insert the entire protective lens drawer assembly back into the handheld welding head and tighten the screws.

1064nm Protection Lens

1064nm transmittance enhancement film with a high damage threshold (> 15J/cm2) coated on the protective lens can effectively increase the transmittance of the lens, reduce energy loss and improve the quality of the processed product. It is widely used in laser cutting, laser welding machine and other laser equipment.

Why the Protective Lens Always Burns Out?

The protective lenses of laser welding machines are consumables and need to be regularly replaced. However, factors such as welding processes, welding techniques, and settings can cause damage, and anomalies in laser output from individual lasers can also lead to frequent burning of protective lenses in laser welding machines. Once the laser protective lens is damaged, work should be stopped immediately and need to replace protective lens for laser welding. Here are methods to avoid burning the protective lens:

1. Check if the auxiliary gas is pure and if the pressure meets the standards. In cases where air is used, check the quality of compressed air.

2. Check if there is any misalignment in the optical path during laser emission, ensuring that other lenses are not damaged during operation.

3. Check if the nozzle aperture is appropriate, avoiding oversized apertures.

4. Check if the air blowing timing configuration is reasonable, ensuring that the software settings are correct.

Common specifications for protective lenses in fiber laser welding machines include diameters (in mm): 50*2, 55*1.5, 78*3, 108*4, 133*5, 133.5*4, and 134*3. The wavelength for these lenses is 1064nm.