HEROLASER

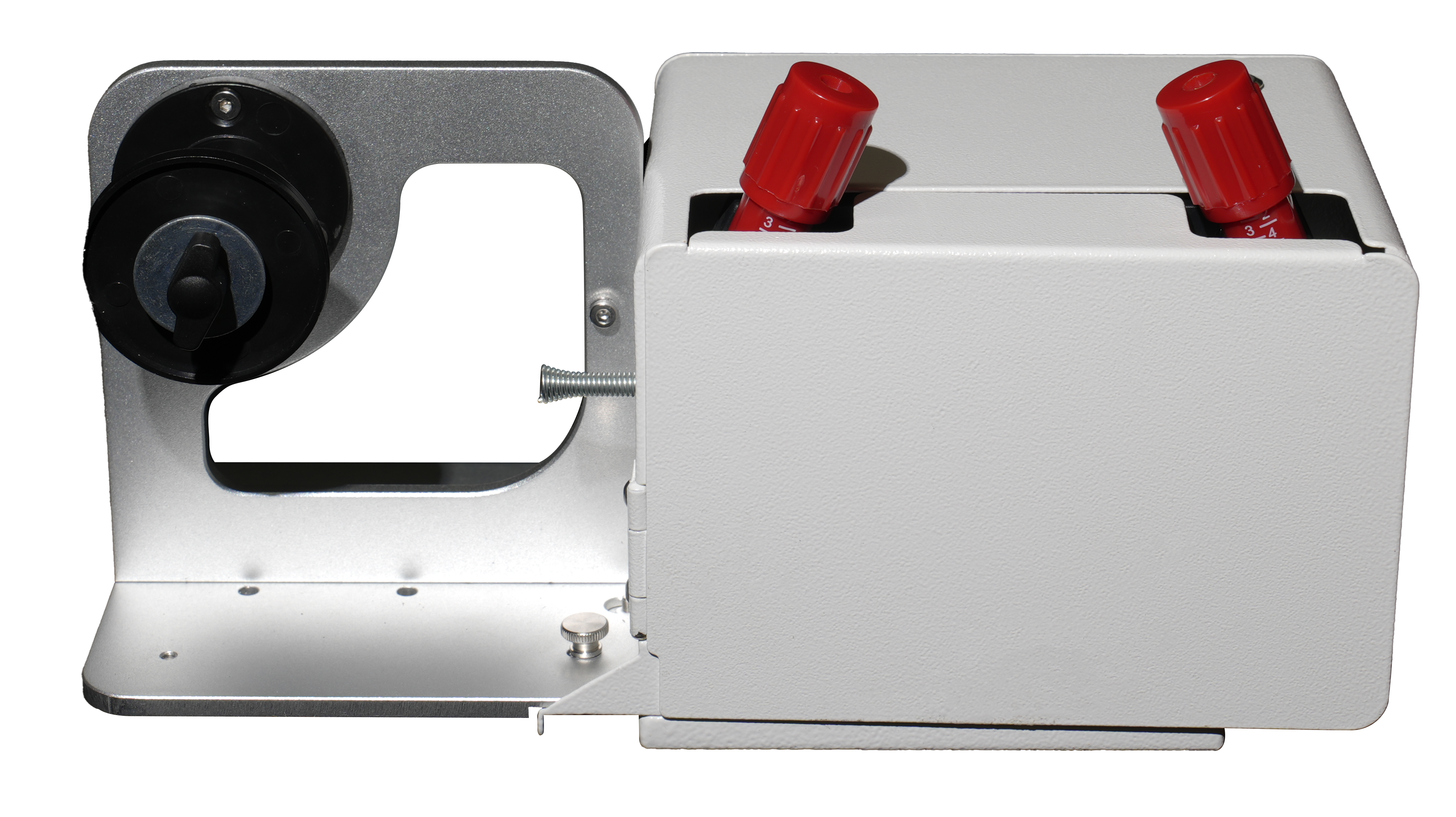

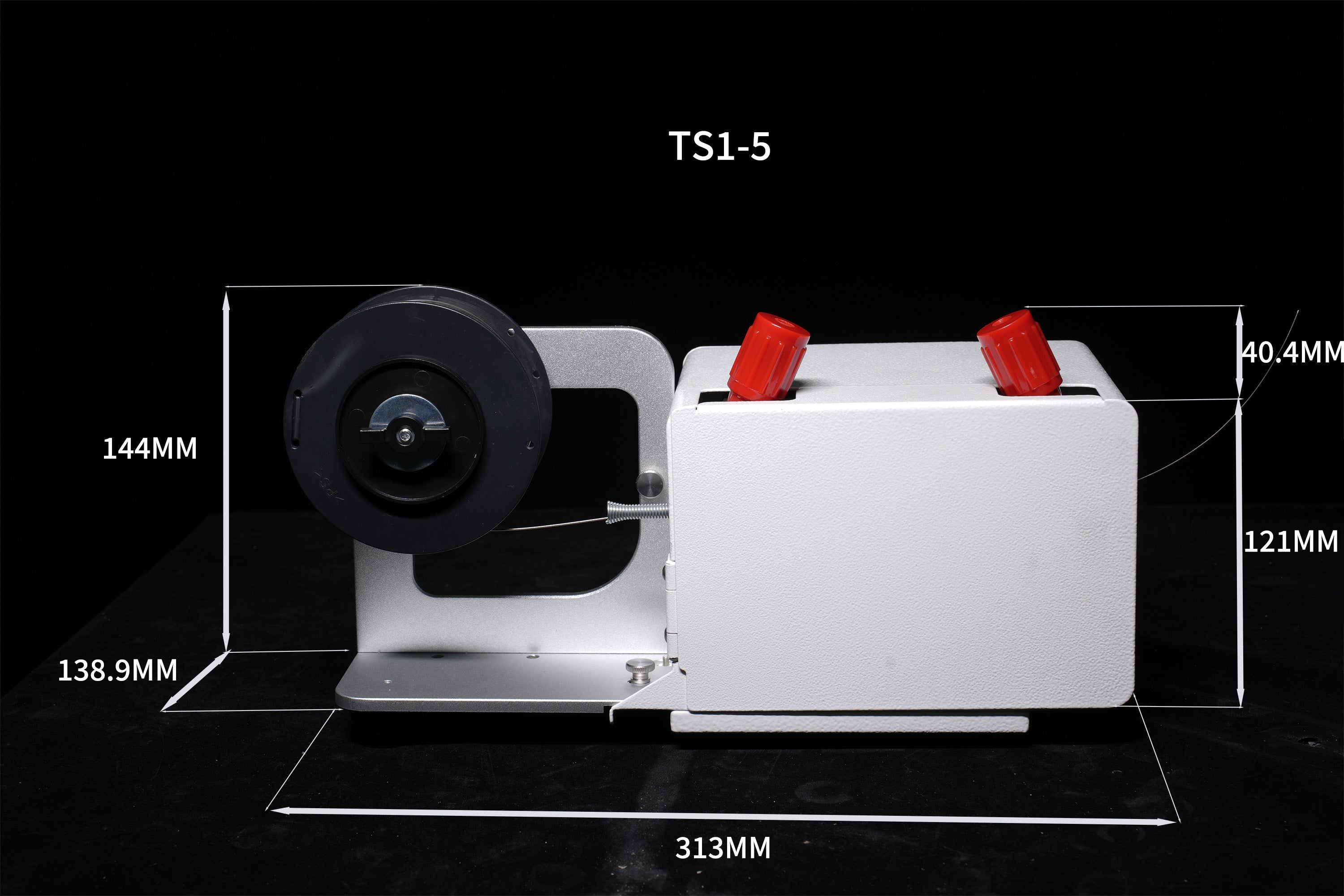

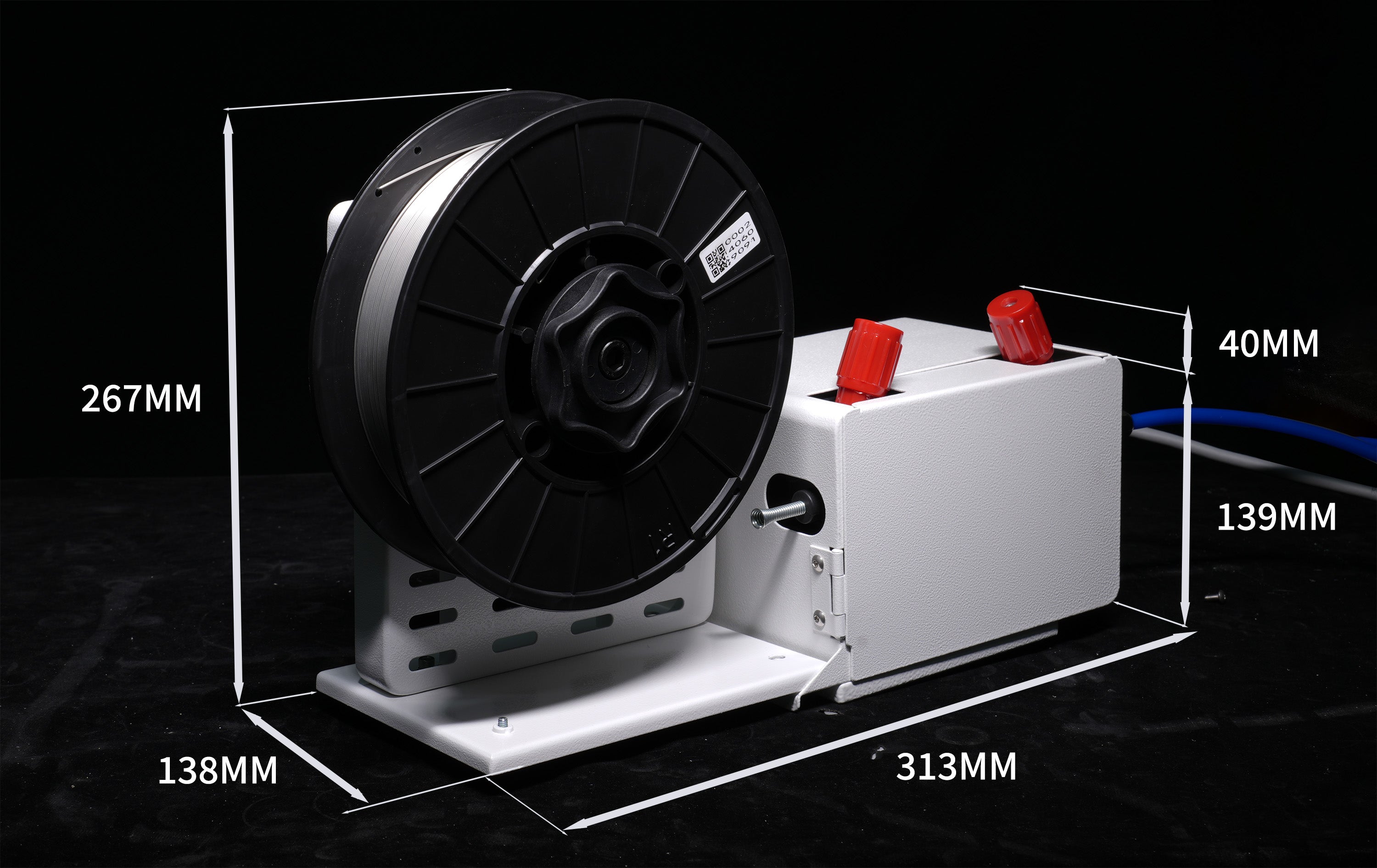

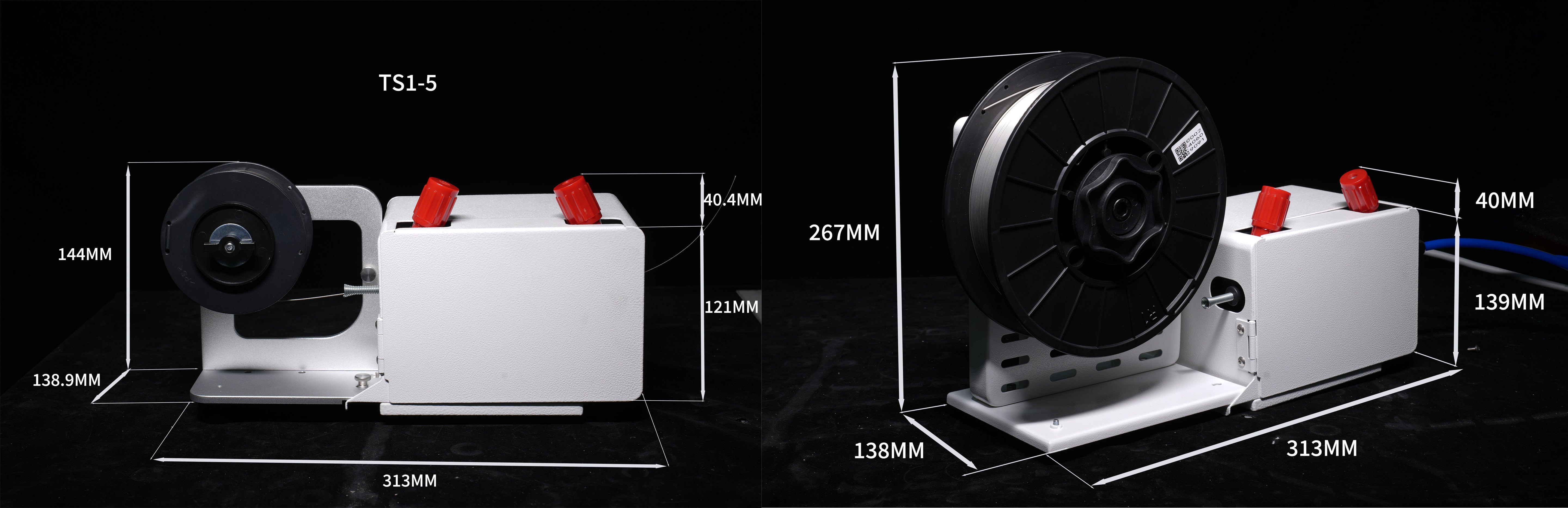

Automatic Welding Wire Feeder TS1-5

Choose options

TS1-5 WIRE FEEDER

Can perfectly adapt to the welding auxiliary wire feeding of our company's laser machine platform Addressing customers' one-stop shopping needs.

Parameter |

Specification |

|---|---|

| Power Supply Voltage | 24V DC |

| Maximum Power Consumption | 60W |

| Operating Temperature | -10°C to 50°C |

| Feed Wire Speed | 5–600 cm/min |

| Feeding Modes | Manual / Automatic |

| Net Weight | 3.6 kg |

| Wire Spool Size | 1–5 kg standard (up to 10 kg optional) |

| Compatible Wire Materials | Carbon steel, stainless steel, aluminum (solid wire) |

The Herolaser Automatic Wire Feeder is engineered for precision, durability, and ease of use in industrial welding and individual welding.

The TS1-5 wire feeding machine is suitable for wire materials with a diameter ranging from 0.8mm to 1.0mm. Free to switch between 1lkg or 5kg wire rolls.

Designed to precisely feed welding wire to the welding point, the wire feeder works in tandem with Herolaser’s welding machines to provide accurate control over the welding process. This synergy enables welders to consistently produce high-quality welds with optimal efficiency.

Automate with AI Laser App

Smart Control

The wire feeder seamlessly integrates with the AI Laser App, allowing for one-click wire feeding and wire rewinding. This intelligent control simplifies operation and increases productivity on the job.